Stainless Sheet Metal Compression

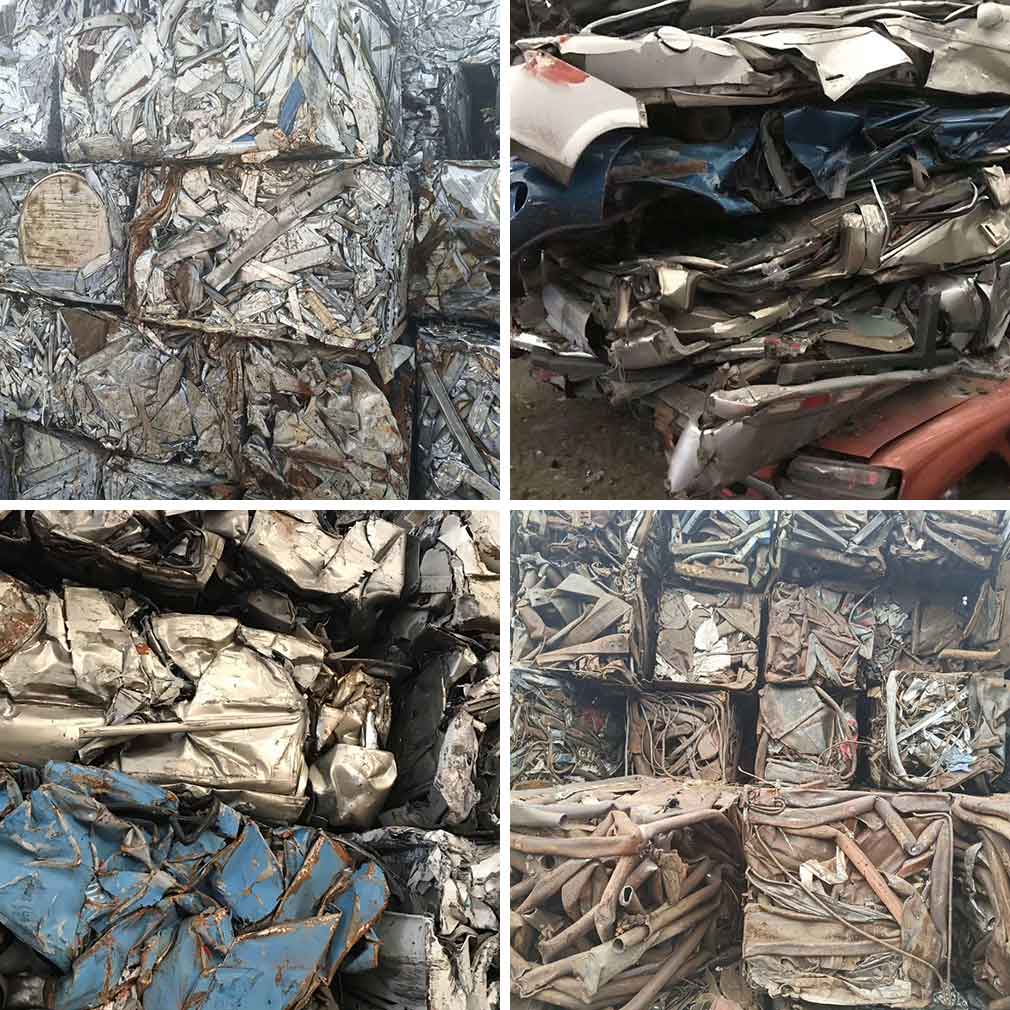

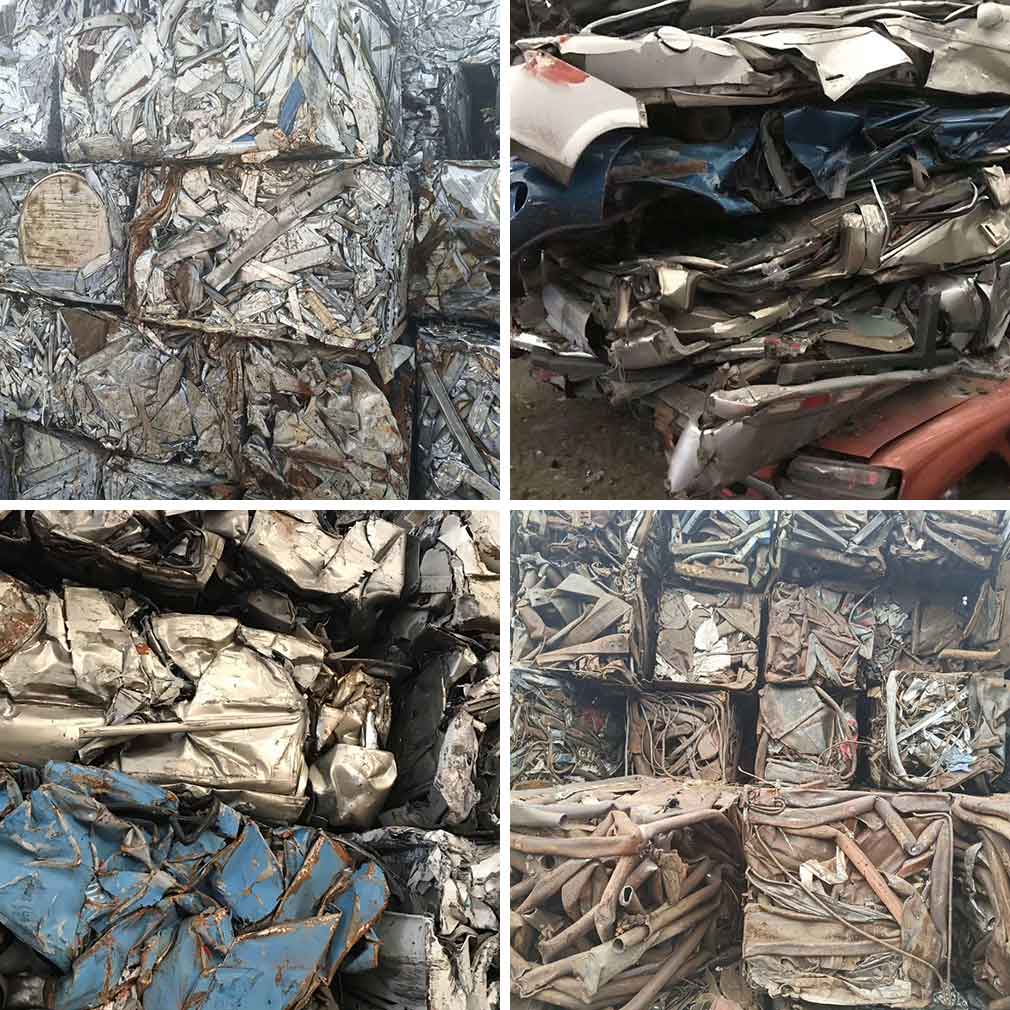

Baler Machine is an industrial equipment designed for the efficient compaction of various types of sheet metal materials, such as aluminum, steel, and copper sheets. This machine is particularly useful in industries that deal with large quantities of scrap metals, as it helps in reducing the volume of waste, making it easier to handle, transport, and recycle.

Key Features of a Stainless Sheet Metal Compression Baler Machine:

1. Durability: Made from stainless steel, these machines are highly resistant to corrosion and wear, ensuring longevity and reliability even in harsh environments.

2. High Compaction Ratio: They are capable of compressing sheet metal materials into dense blocks, significantly reducing their volume. This can increase storage capacity and facilitate transportation.

3. Safety Features: Most modern balers include safety features like interlocks, emergency stop buttons, and protective barriers to ensure operator safety during operation.

4. Customization Options: Depending on the specific needs of the industry or the type of material being processed, balers can be customized with different configurations, such as hydraulic systems, automatic tie mechanisms, or varying compaction pressures.

5. Efficiency and Productivity: By efficiently compacting scrap metal, these machines help in optimizing space usage, reducing labor costs associated with handling larger volumes of material, and improving overall production efficiency.

6. Environmental Benefits: By reducing the volume of waste, these machines contribute to environmental sustainability by facilitating more efficient recycling processes and minimizing landfill use. #

Operation Process:

- Material Input: Scrap metal sheets are fed into the machine through a designated entry point.

- Compaction: The machine applies pressure to compress the metal sheets into a compacted block.

- Tying: An automatic or manual mechanism ties the compressed block securely to prevent any movement during transportation.

- Output: The compacted blocks are then removed and can be stored or transported for further processing or recycling. Industries Using Stainless Sheet Metal Compression Balers: These machines are commonly used in various industries including automotive manufacturing, aerospace, construction, and recycling facilities where the efficient management of metal waste is crucial.

Maintenance and Care: Regular maintenance, including cleaning, oiling moving parts, and checking for any damages or malfunctions, is essential to keep the machine running smoothly and prolong its lifespan.

By investing in a Stainless Sheet Metal Compression Baler Machine, industries can streamline their waste management processes, enhance operational efficiency, and contribute positively to environmental sustainability.

We not only have these baler machine, but have other machines such as Egypt Two Ram Stainless ScrapCompactor,Romania Factory Price Stainless Steel shavings block making machine,Dalongkai baler Integral Copper Scrap Cutter Machine,Poland High Density Hydraulic

Briquetting Machine for brass borings,Shengbo baler Scrap Baler 135tons press machine,Thailand Automatic Cast Iron sawrfs block making machine,Qatar Scrap Compactor Machine,Denmark 250Ton Metal Sheet Crocodile Shear,Australia High Quality Scrap Metal Chip Press Machine,Belgium Gaode

Scrap Metal Baler,Wanshida baler High Density cast iron Chips briquette machine,Spain Metal Swarf Briquettes press,Argentina SBJ aluminum Chips briquetter,Canada High density briquetter for Stainless Steel powder,Japan China Brass Turnings briquetting machine,Albania Vertical Iron Scrap Shear Machine,Kuwait Automatic Copper Scrap Baling Press,India Automatic Brass Borings briquette machine,Norway China steel Chips briquette machine,Enerpat baler Integrated Copper Scrap Crocodile Shear,Singapore Non Ferrous Metal Scrap Compressing Machine,Finland Automatic baler for Stainless Steel chips,Bulgaria Powerful Steel Wire Baling Press,Huahong baler Small Copper Scrap Crocodile Shear,Mexico Automatic briquette machine for Steel chips,South Africa Low cost Bronze Turnings

Briquetting Press,Russia Iron Scrap Baling Machine Cost,Aupu machinery baler Factory price Copper Shavings briquetting machine,Greece Low Cost Steel Millings briquetting machine,Malaysia Vertical Metal Scrap

Cutting Machine,America Hydraulic briquetting machine for Aluminum turnings,Turkey Vertical

Aluminum Drillings Briquetting Press,Slovenia Q43 Scrap Metal Cutter Machine,Jiangyin supplier Best performance aluminum Powder briquetter,Iran SBJ metal Chips baler,Dongfang hydraulic Hydraulic Copper Scrap Packing Baler,Chile China metal Borings briquetting machine,Croatia Aluminium Scrap

Hydraulic Baling Press,Oman Metal Srap Compress Machine,Iraq Metal Chips Hydraulic Briquetting Press etc...

Please contact with us if you have any questions.

Parameters:

| Model | CMS125 | CMS160 | CMS200 | CMS250 | CMS315 |

| Chamber Size | 1400x800x300mm | 1500x1000x350mm | 1800x1400x400mm | 2000x1400x450mm | 2200x1400x500mm |

| Bale Size | 300x300mm | 350x350mm | 400x400mm | 450x450mm | 500x500mm |

| Bale Weight | 30-50kg | 60-100kg | 80-150kg | 120-180kg | 150-250kg |

| Motor Power | 30kw | 37kw | 2x30kw | 2x37kw | 2x45kw |

| Machine Weight | 6850kg | 9670kg | 13450kg | 18650kg | 25780kg |

| Machine Size | 3980x2340x1880mm | 4240x2540x2330mm | 4530x2890x2340mm | 4860x3120x2250mm | 5320x3350x2360mm |

Features:

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Schneider electrical components prolong the service life of the machine.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Enough spare parts with lower cost to keep the machine non-stop.

> Remote Control is optional, can archive automatic operation without worker.

> Lifelong after services let you have no any concern, get more porfits.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

FAQ:

> What is payment term of Iron Tins Scrap Pressing Machine?

The payment of the baler machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the baler machine.

> How to operate Aluminum Can Compactor?

This baler is very simple, just operate per user manual is ok, you can contact with us if you have any questions any time, we can guide you how to operate the baler machine.

> How can i know you are a manufacturer or trader of Non Ferrous Metal Scrap

Packaging Machine?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> How much price of Stainless Sheet Metal Balers?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> What are the service requirements of the Zip Top Cans Press Baler?

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

> Are the interchangeable wear plate installed on Zip Top Cans Compactor?

Yes, the wear steel plate is changeable, you can easily change it when which wear plate is going to change, and we also can weld the wear plate directly, because this way, it is durable ans stable.

> What is pump flow of UBC Baling Press?

The pump flow of the baler machine is diffent depending on different models, in a word, small models baler machine will have small pump flow, and bigger baler will use bigger pump flow accordingly.