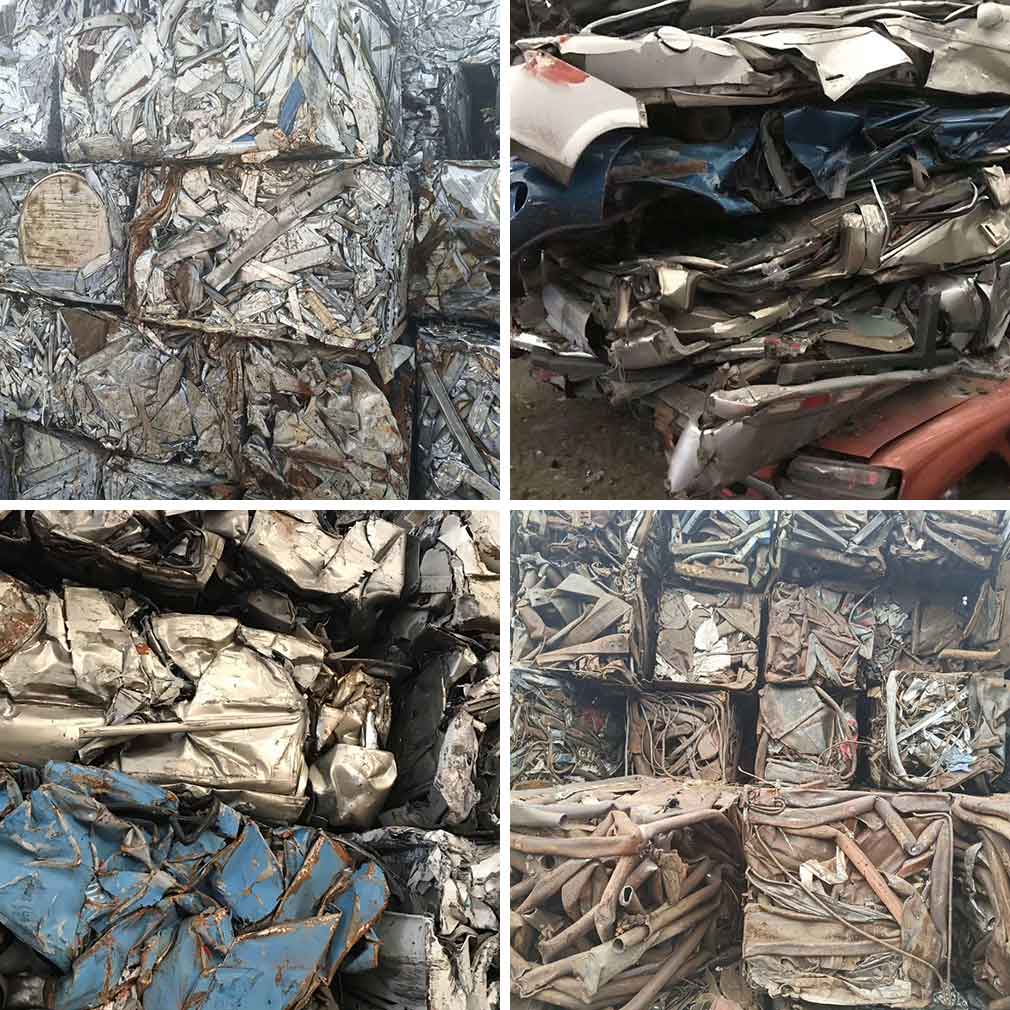

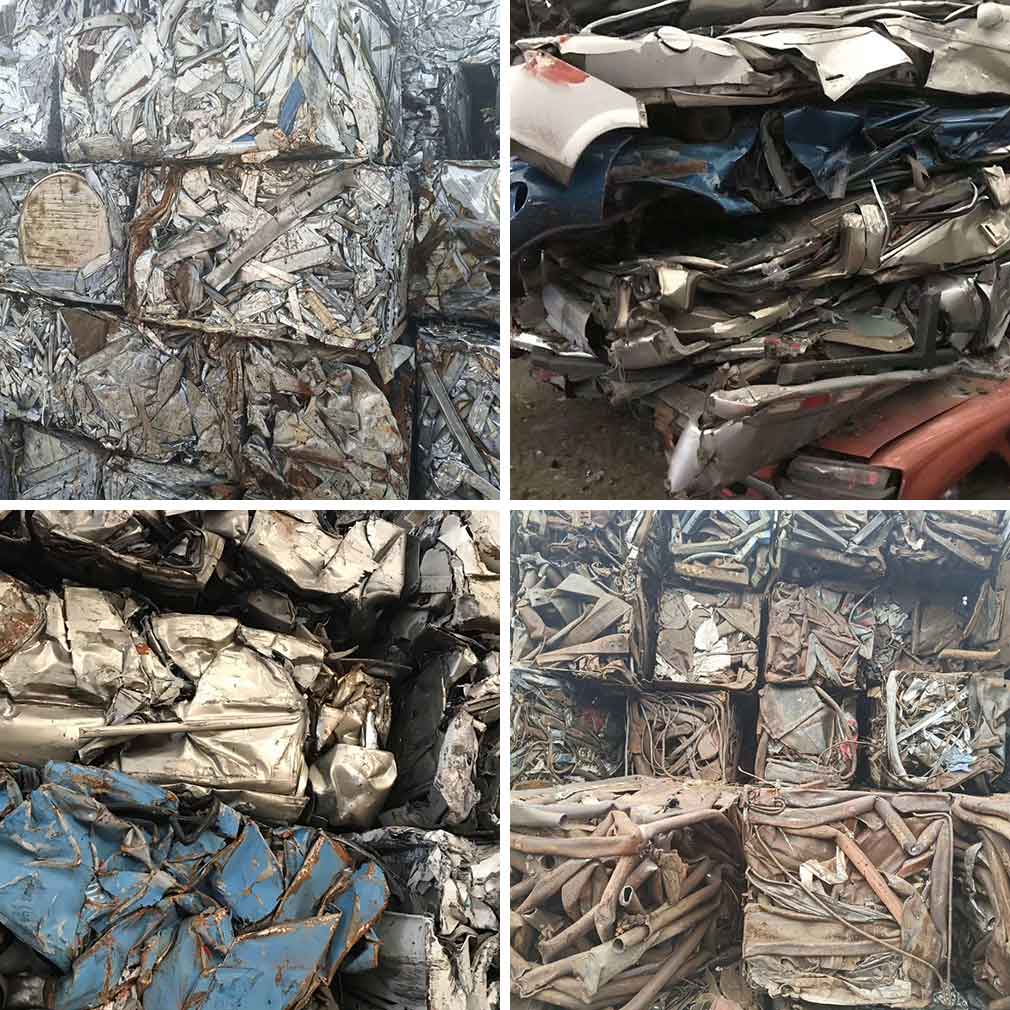

Continuous steel scrap baling press machine is an industrial equipment designed for the efficient compaction of steel scrap or metal waste into compacted bales. This type of machinery is commonly utilized in recycling facilities, scrap yards, and metal processing industries to facilitate easier handling, storage, transportation, and further processing of scrap metals.

Key Features:

1. High Capacity: These machines can handle large volumes of scrap steel, making them suitable for high-throughput operations.

2. Efficiency: They are designed to operate continuously, reducing downtime and increasing productivity.

3. Automation: Many models come equipped with automation features that help in maintaining consistent bale size and quality, improving operational efficiency.

4. Safety Features: Modern machines include safety features such as emergency stop buttons, interlocks, and safety guards to ensure operator safety.

5. Customizability: Depending on the specific needs of the user, these machines can be customized in terms of size, capacity, and additional functionalities like automatic bale ejection systems.

6. Environmental Benefits: By compacting scrap metal, these machines help reduce the environmental impact by minimizing the space required for storage and transportation.

Operation:

The process typically involves feeding steel scrap into the machine through a hopper or conveyor system. The machine then compresses the material using hydraulic pressure, forming it into a compact bale. The bale is then ejected from the machine, ready for further processing or storage.

Benefits:

- Cost Savings: Reduces the cost associated with storage, transportation, and handling of scrap metal.

- Space Efficiency: Smaller storage spaces are needed due to the compact size of baled materials.

- Environmental Impact Reduction: Helps in reducing greenhouse gas emissions by decreasing transportation distances and optimizing the use of resources.

- Sustainability: Promotes recycling and reprocessing of metal waste, contributing to a more sustainable industry.

Maintenance and Safety: Regular maintenance is crucial to ensure the longevity and optimal performance of the machine. This includes checking and replacing worn-out parts, ensuring hydraulic systems are clean and well-lubricated, and conducting routine safety checks to prevent accidents.

Conclusion: Continuous steel scrap baling press machines are essential tools in the metal recycling industry, offering significant benefits in terms of efficiency, cost-effectiveness, and environmental sustainability. Their ability to automate and streamline the process of steel scrap management makes them indispensable in modern recycling operations.

We not only have these

Baler Machine, but have other machines such as Dongfang hydraulic 315Ton Waste Rebar Crocodile Shear,Aupu machinery baler 250Ton Waste Rebar Shear Machine,Wanshida baler Aluminum Can Compressor,Eco hydraulic 250Ton Light Metal Compress Baler,Romania Low Price Waste Cans Baling Press,Russia Y83 Steel Drillings briquetter,America Two Ram Aluminum Tins Baler,Malaysia 315Ton Metal Sheet

Alligator Shear,Australia Y81Q Light Metal Baling Press,Thailand Stainless Sheet Metal Hydraulic Press Machine,Mexico Waste Steel Shear,Singapore China Supplier Aluminum Cans Baling Machine,South Africa Machine Press Aluminium Cans,Norway Hydraulic Metal Chips Baler,Ecuador Factory price Copper Powder briquetter,Finland Automatic Tinplate Compress Baler,Netherlands SBJ Metal sawrfs block making machine,Britain Turn Out

Metal Scrap Baler,Greece Best performance Bronze Borings

Briquetting Press,Sri Lanka Automatic baler for Aluminum shavings,Sweden Cheap Iron

Scrap Shear With Conveyor,Huahong baler Aluminum Can Baler Plans,Iceland Shearing Alligator Shape Shearing Machine For Sale,Kuwait Y83 baling machine for Aluminum powder,Enerpat baler 125 Tons Zip Top Cans Press Baler,India Y83 briqeutting press for Aluminum shavings,Chuangda baler JiangYin Manufacturer Waste Steel Baler,Indonesia Automatic Round Bar Shear With Conveyor,USA Movable Metal Sheet Cutter Machine,Spain Used Scrap Metal Balers For Sale,New Zealand Factory Price Metal Millings Blok Making Machine,Argentina Automatic Cast Iron Drillings briquetting press,Dalongkai baler Vertical metal Powder briquette machine,Jiangyin manufacturer Mobile scrap shear metal shear hydralic,Turkey High quality metal Turnings

Briquetting Machine,Pakistan Heavy duty metal scrap shear,Jiangyin supplier La Bonti Scrap Shear,Croatia Two Ram Used Beverage Cans Compactor Machine,Slovenia Automatic aluminum Shavings briquetting press,Denmark Tin Can Compress Baler etc...

Please contact with us if you have any questions.

Parameters:

| Model | CMS160 | CMS200 | CMS250 |

| Chamber Size | 1500x1000x350mm | 1800x1400x400mm | 2000x1400x450mm |

| Bale Size | 350x350mm | 400x400mm | 450x450mm |

| Bale Weight | 60-100kg | 80-150kg | 120-180kg |

| Motor Power | 37kw | 2x30kw | 2x37kw |

| Machine Weight | 9670kg | 13450kg | 18650kg |

| Machine Size | 4240x2540x2330mm | 4530x2890x2340mm | 4860x3120x2250mm |

Features:

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> The bale weight ranges from 20kg to 300kg, more options for your choices.

> Cycle time can be upto 30 seconds, and 120bales per hour, more efficiently, can help you save lots of money.

> Adopts china famous pump to keep baler machine run smoothly.

> Adopts simple structure, easy to operate and maintain.

> Adopts Two rams structure to keep high bale density.

FAQ:

> How much would Non Ferrous Metal Scrap Press Compactor , its installation, and training cost me?

The price of baler machine is different according to different bale size, bale weight and output capacity as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.

> What is warranty term of the Tin Press Bundle Machine?

Within the guarantee period, in the event of any malfunction caused by the quality of the commodity, we provide free components for replacement. Wear parts are exclusive from this warranty. We also provide technical support for the whole lifespan of the machine.

> What is lead time of Stainless Steel Press Machine?

The lead time is various according to different models, generally speaking, it is approx. 30 days, and will be longer with bigger models, and shorter with small models, we will work overtime if you need the baler machine urgently.

> Are you a manufacturer or a trader of Tinplate Scrap Compactor Machine?

We are true manufacturer of

Scrap Metal Baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> What are all the skills required to operate a Stainless Steel Baling Press Machine manufactured by Diloya?

No special skills, just read the user manual carefully before operating the baler machine, if you have any questions, feel free to contact with us, we can help you at any time.

> What are the service requirements of the Aluminium Scrap Baling Press Machine?

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

> What is payment term of Aluminium Ubc Scrap Packing Machine?

The payment of the baler machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the baler machine.