Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: HBD300

Brand: DILOYA

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Motor, Pump

Warranty Period: 1 Year

Out-of-warranty Service: Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Pakistan, Australia

Applicable Industry: Other

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Romania, Kenya

Control Type: Automatic Control;

Warranty Time: 12Months;

Bulk Density: up to 0.5t/m3;

Loading Container: 20GP;

Bale Weight: 10-60kg;

Motor Brand: China famous brand;

Packaging: Nude Packaging

Productivity: 3-5tons/hour

Transportation: Ocean

Place of Origin: Shanghai China

Supply Ability: 50sets/month

Certificate: ISO9001/TUV

HS Code: 8422400090

Port: Shanghai Port,Qingdao port

Payment Type: T/T,L/C

Incoterm: FOB,CIF

The corn cob press bagging machine is a type of machinery used to compress and package corn cobs for storage or transportation. The machine typically consists of a hopper or conveyor system that feeds the corn cobs into a compression chamber. Once inside the chamber, hydraulic or mechanical pressure is applied to compress the corn cobs into a compact form.

After compression, the corn cobs are then transferred to a bagging system where they are placed into bags or sacks. The bagging system may use a conveyor belt, robotic arm, or other mechanisms to fill and seal the bags. The bags are typically made of durable materials such as woven polypropylene or jute to ensure the corn cobs are protected during storage or shipping.

Corn cob press bagging machines are commonly used in agricultural and biomass industries where corn cobs are utilized as a fuel source, animal bedding, or as a raw material for manufacturing processes. These machines increase efficiency and reduce labor costs by automating the compression and bagging process, allowing for faster production and consistent packaging.

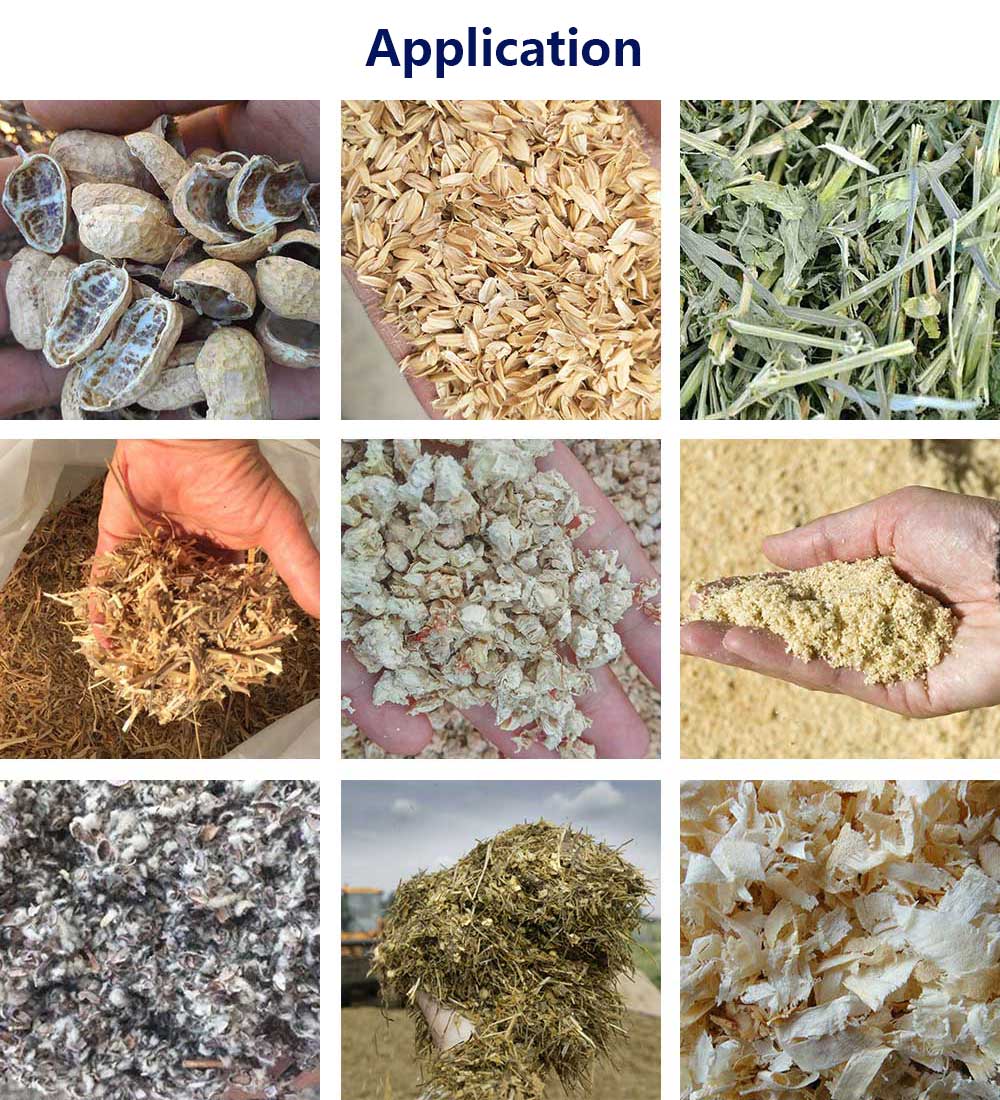

The Full Auto Maize Cob Compactor Machine is mainly compress the wood shviangs, corn silage, wood sawdust, cotton hulls, rice husks, corncob, peanut shells, haylage, alfalfa hay straw etc into small bales with high density for annimal feedings and beddings and other purposes, easy to transport, stock and convenient for distributor to sell to end users, it has other names such as Corn Cob Compress Bagging Machine,High Density Corncob flakes Baler Machine,Hydraulic Corncob flakes Compactor Machine,Three Rams Corn Cob Compactor Machine,Hydraulic Corncob flakes Baler,Corn cob core Compress Packer Machine,Automatic Corncob Powder Bagging Machine,High Density Corn Core Baler,Hydraulic Corncob flakes Baling Machine.

We not only have these baler machine, but have other machines such as Horizontal Rice Husks Bagging Machine, Rice Husk Bag Bagging Press Machine 25 Kg, Wood Sawdust Bagging Baler Machine, Corn Silage Baling Press Baler, Horizontal Animal Feedings Bagging Machine, Bale press machine for wood shaving sawdust peanut shell, Hydraulic Rice Hulls Baling Press Machine, Rice Husks Press Baler, Scale Weighing Wood Sawdusts Baling Press Machine, Hydraulic pressing used for silage grass, Scale weighing Animal Feedings Baler Machine, High Speed Alfalfa Chaff Square Press Baler, India Rice Husks Compactor, China Supplier Wood Chips Packing Machine, High Density Corn Core Baling Press, Horizontal Corncob meals Compactor, China Supplier Wood Chips Bagging Machine, Three Rams Corncob meals Bagging Machine, Horizontal Corncob flakes Baling Machine, Automatic Wheat Husks Baling Press, China Corn Cob Baler, Horizontal Corncob meals Bagging Press, Horizontal Two Rams Alfalfa Hay Bagging Press, 2kg Animal beddings Baling Press, Chopped Straw Animal beddings Compressor Machine, Hydraulic Wood Sawdusts Compressor Machine, Diloya Animal Feedings Bagging Machine, Sawdust press panel, India Wheat Husks Compressor Machine, Big Bale Rice Chaff Baling Press Machine, China Supplier Wood Chips Bagging Baler, Scale Weighing Cotton Seed Hulls Bagging Baler, Big Bale Alfalfa Chaff Baling Machine, High Speed Wheat Straw Compress baler, Rice Husks Bagging Press Machine, Corn Silage Bagging Machine, Full Auto Rice Husks Compactor, China Corncob meals Baler, Horizontal Rice Husks Packing Machine, Fully Auto Corncob flakes Bagging Press etc...

| Model | HBD100 | HBD150 | HBD200 | HBD250 | HBD300 | HBD400 |

| Bale Size | 500x300x200mm | 600x300x300mm | 700x400x300mm | 750x430x310mm | 750x430x310mm | 750x430x310mm |

| Chambe Size | 1000x500x600mm | 1100x600x600mm | 1200x700x800mm | 1400x700x800mm | 1400x700x800mm | 1400x700x800mm |

| Bale Weight | 10-20kg | 15-30kg | 20-40kg | 25-50kg | 30-50kg | 40-60kg |

| Motor Power | 18.5kw | 22kw | 30kw | 37kw | 45kw | 55kw |

| Machine Weight | 2150kg | 3780kg | 5360kg | 6540kg | 7320kg | 8670kg |

| Machine Size | 2550x1530x1980mm | 3230x2120x2410mm | 3450x2150x2550mm | 3850x2330x2680mm | 3850x2350x2710mm | 3950x2540x2650mm |

> Latest design of the machine to let you use the best the machine all the time.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Schneider electrical components prolong the service life of the machine.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> How much is the shipping cost of Three Rams Corncob granules Compressor Machine?

The shipping cost is varying over time,and different models of baler machine will need different containers to hold, if peak season and bigger models, the shipping cost will be higher, and on the contrary, the cost will be lower.

> Before shipment, can you take testing video of Corncob Compactor Bagging Machine?

Yes, of course, we not only can take a video of machine running before shipment, we also can take videos, photos of the process of manufacturing the baler for you.

> How can we install the 30kg Corncob meals Compressor?

The baler machine is marked tips when shipping, and you can easily assemble the machine per the tips, after assembling, put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is ok, if you have any questions, you can contact with us any time.

> What is warranty time of the Horizontal Corn Cob Baling Press Machine?

The warranty time of the baler machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> Does Hydraulic Corncob Powder Baling Press Machine have PLC control?

Yes, the machine has PLC automatic control, easy to operate and more efficient, and also has manual control, easy to debug and maintain the baler machine.

Product Categories : Bagging Press Baler > Corn Cob Bagging Baler

Home > Products > Bagging Press Baler > Corn Cob Bagging Baler > Corn Cob Press Bagging Machine

Send Inquiry

Mr. Scott

Tel:0086-188-1766-8272

Fax:

Mobile Phone:+8618817668272

Email:sales@diloya.com

Address:No. 888, HuanHu West 2 Road, PuDong New Area

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.