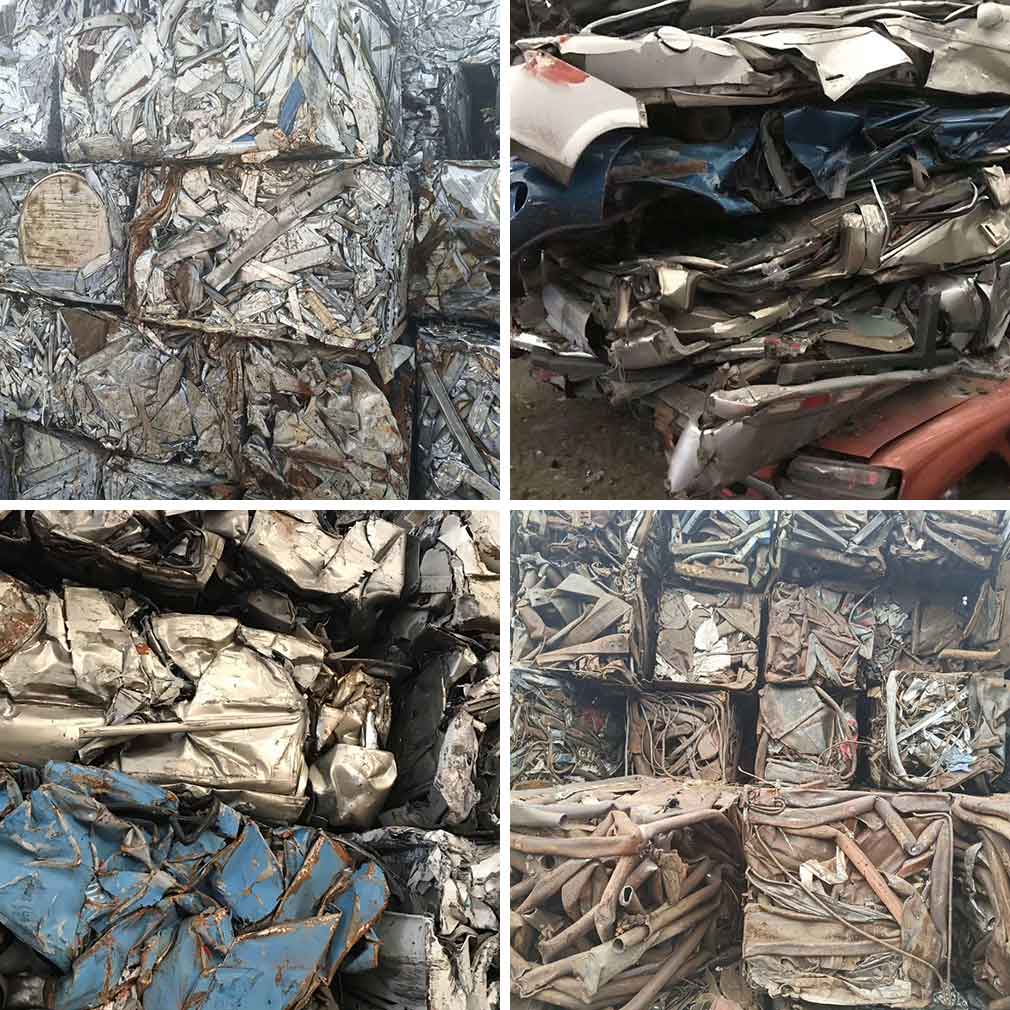

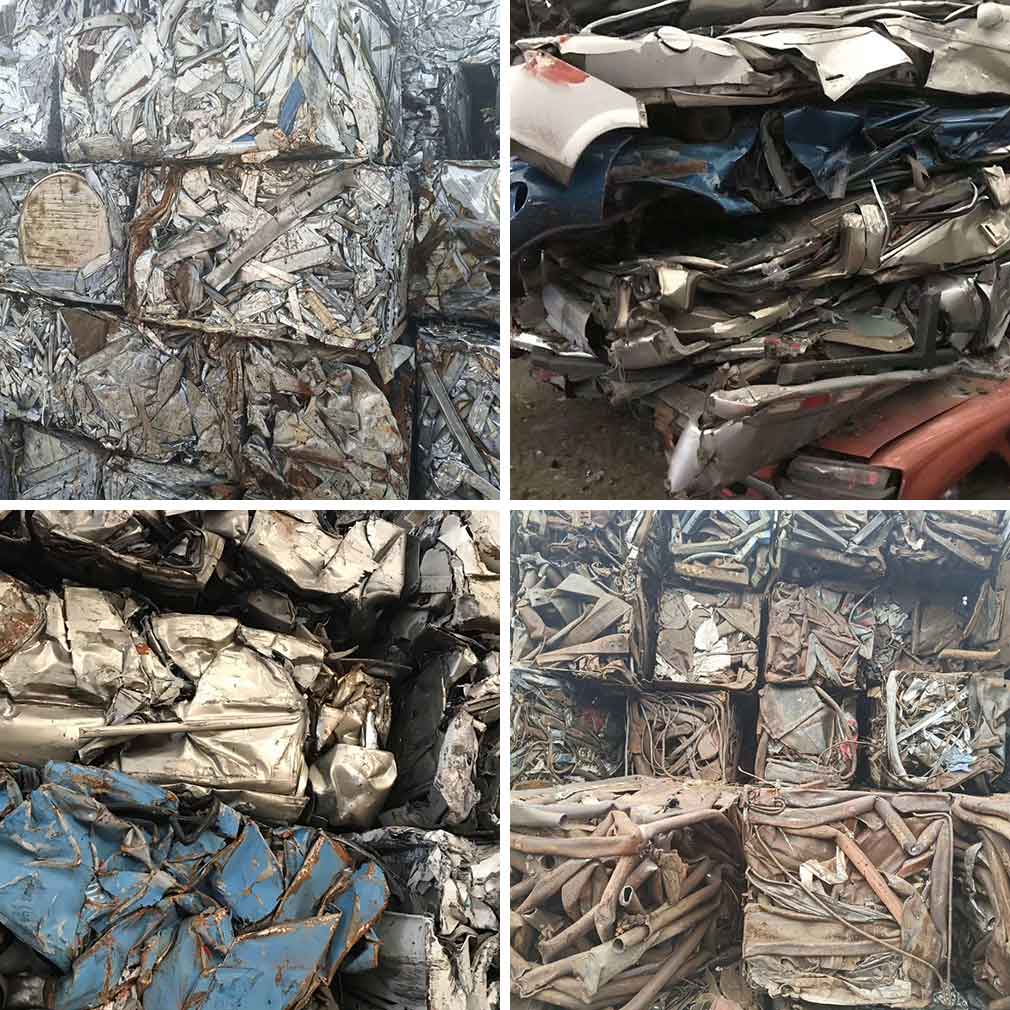

Scrap Metal Baler Press Machine is a type of industrial equipment used for compressing scrap metal into compact, manageable blocks or bales.

This process is beneficial for several reasons:

1. Space Saving: By compressing scrap metal, the volume of the material is significantly reduced, making it easier to store and transport.

2. Efficiency in Handling: Baled scrap metal is easier to handle during transportation and storage. It can be stacked more efficiently than loose metal pieces.

3. Economical Transportation: Smaller volumes mean less space on trucks or containers, which reduces transportation costs.

4. Sustainability: Compressing scrap metal helps in reducing the environmental impact by minimizing the space needed for storage and facilitating recycling processes.

Components of a Scrap Metal Baler Press Machine:

- Frame: The main structure that supports all other components.

- Hydraulic System: Responsible for providing the force needed to compress the metal.

- Bale Forming Cylinder: This cylinder moves up and down to compress the metal into a bale.

- Control Panel: Allows operators to control the machine's functions, including speed and pressure settings.

- Safety Features: Important for operator safety, these may include interlocks, emergency stop buttons, and safety guards around moving parts.

Operation:

1. Loading: The scrap metal is loaded into the hopper or conveyor system that feeds the machine.

2. Compression: The hydraulic system applies force through the bale forming cylinder, compressing the metal until it reaches the desired size and density.

3. Bale Formation: As the metal is compressed, it is shaped into a bale. The machine typically has a fixed size for the bales to ensure they fit into standard shipping containers or storage areas.

4. Discharge: Once the bale is formed, it is ejected from the machine. Some models have an automatic discharge mechanism, while others require manual handling.

Maintenance:

Regular maintenance is crucial to ensure the machine operates efficiently and safely. This includes checking and replacing worn-out parts like seals, filters, and hydraulic fluid, as well as lubricating moving parts.

Regulatory Compliance:

In many regions, there are regulations regarding the safe operation of such machinery, especially concerning noise levels, emissions, and worker safety. Compliance with local and international standards ensures the operation of the machine within legal boundaries.

We not only have these Baler Machine , but have other machines such as Chile 100Ton Used Metal Compactor Machine,Shengbo baler Automatic Copper Swarfs baling machine,Iran Aluminum Tin Cans Baler Diesel,Netherlands Factory Price Brass chips block making machine,India China Supplier Pop Cans Compactor Machine,Denmark India Alu Cans Tins Packing Baler,Norway Steel Aluminium Press 200 T,Singapore Vertical

Briquetting Machine for Metal powder,SK BalerMetal Wire Baling Machines,Iraq Vertical Stainless Steel Drillings baling machine,Chuangda baler High Density Hydraulic

Briquetting Press for brass millings,America Low Cost Copper chips block making machine,USA High Speed Aluminum Cans Recycling Baler,Dongfang hydraulic Vertical Brass Shavings baling machine,Portugal Automatic baler for Steel shavings,Japan Factory price cast iron Chips briquetter,Croatia High quality steel Borings briquetting machine,Britain High density briqeutting press for Aluminum millings,Enerpat baler China Copper Hair Wire briquetting machine,Indonesia Push Out

Iron Scrap Baler,Slovenia India Copper Scrap Recycling Baler,Egypt

Aluminium Briquetting Press machine,Belgium Aluminium Used Beverage Cans Baling Machine China,Ruf briquetting press Low Price Pop-Top Cans Baling Press,Finland Automatic briquetting machine for Metal powder,Spain 315Ton Metal Scrap Alligator Cutter,Australia China Stainless Steel Drillings briquetting machine,Gaode baler, Fast UBC Compress Baler,Italy Sheet Metal Scrap Pressing baler,Pakistan Vertical Copper Shavings briquetting press,France Heavy Duty Waste Bar Baler,Wanshida baler Automatic baling machine for Steel drillings,Eco hydraulic Y83 Steel Millings briquetter,Dalongkai baler Scrap metal Baler Press Machine Price,Bulgaria Integrated Metal Scrap

Alligator Shear,Malaysia High density baler for Metal chips,Poland 315Ton Steel Plate Alligator Cutter,Sweden High Density Hydraulic Briquetting machine for brass turnings,Albania Hight Speed Ring-Pull Cans Baler With Conveyor,Argentina High Density metal Powder briquetting machine etc...

Please contact with us if you have any questions.

Parameters:

| Model | CM200 | CM250 | CM315 |

| Chamber Size | 1800x1400x900mm | 2000x1400x1000mm | 2500x1400x1200mm |

| Bale Size | 450x450mm | 500x500mm | 600x600mm |

| Bale Weight | 120-200kg | 150-300kg | 400-600kg |

| Bale Density | 80-1200kg/m3 | 800-1200kg/m3 | 800-1200kg/m3 |

| Motor Power | 37kw | 22x2kw | 37x2kw |

| Machine Weight | 16430kg | 19850kg | 28560kg |

| Machine Size | 4560x2650x2350mm | 4860x2980x2430mm | 5120x3150x2540mm |

Features:

> Output capacity can be up to 20-30bales per hour, more efficient.

> Adopts china famous pump to keep baler machine run smoothly.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Stable hydraulic system to keep the machine run well.

> Enough spare parts with lower cost to keep the machine non-stop.

> Latest design of the machine to let you use the best the machine all the time.

> Remote Control is optional, can archive automatic operation without worker.

FAQ:

> Are you a manufacturer or a trader of Remote Control Waste Steel Compactor Machine?

We are true manufacturer of scrap metal baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> Where to find cheap Y81T Used Metal Compactor Machine?

You can search the

Metal Scrap Baler machine which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

> What is voltage of 100Ton Scrap Metal Baler?

For the voltage of the machine, no need to worry about that, we will customize the motor per your local voltage and frequency, and the important thing that the baler machine must need 3 phases electrical power supply.

> How to maintain Hydraulic Metal Compactor?

When you were operating the baler machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

We use China Standard grate steel Q235 to assemble the main frame of the baler machine, and we also can make the machine per your requirement.

> What bale size does the Y81T-1600 Integral Structure Scrap Metal Baler produce?

We can customize the bale size per your requirement, also you can tell us your requirement, we can suggest you suitable bale size accordingly.

> How much would Inida Light Metal Press Baler , its installation, and training cost me?

The price of baler machine is different according to different bale size, bale weight and output capacity as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.