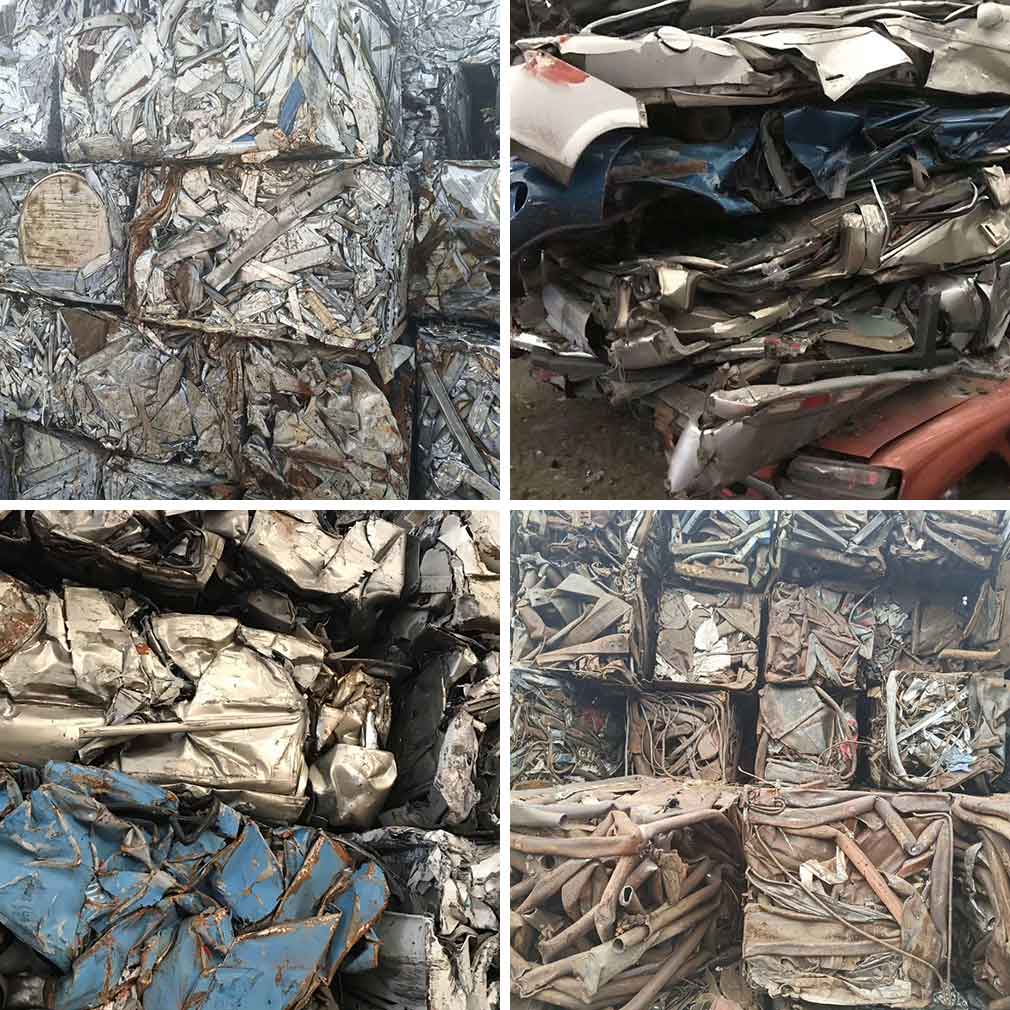

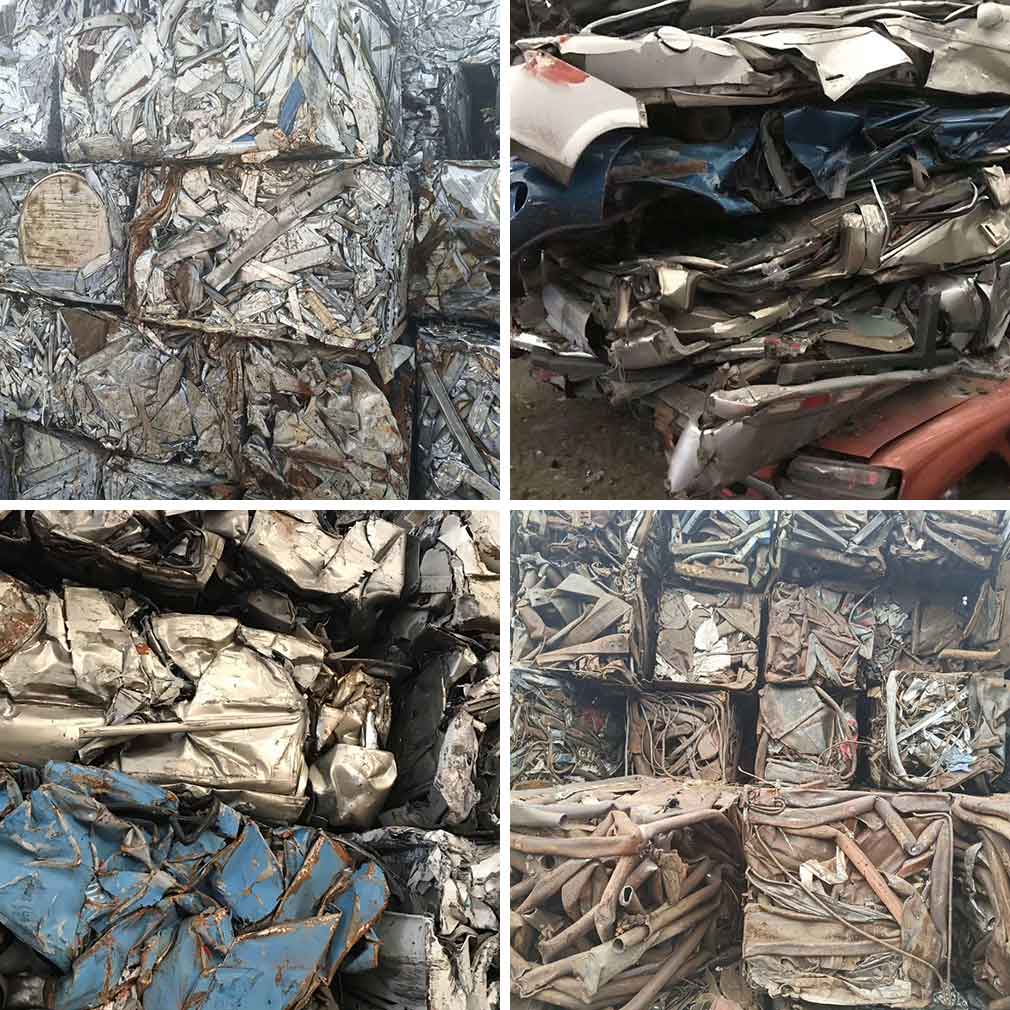

Metal Scrap Baling Press Machine is a specialized industrial equipment designed for compacting and bundling scrap metals into manageable rectangular bales. This process is crucial in the recycling industry, as it helps in reducing the volume of scrap metal, making it easier to transport and store.

Here's a detailed look at the machine and its operation:

Key Components and Features

1. Hydraulic System: This is the core component that powers the press, enabling the force needed to compress the metal scraps. It typically includes a pump, valves, cylinders, and hydraulic oil.

2. Frame: The frame provides structural support to the machine and houses the components necessary for the operation, including the hydraulic system, control panel, and safety features.

3. Compaction Cylinder: This cylinder is responsible for applying the force to compress the metal scraps into a bale. It moves up and down to pack the material tightly.

4. Feeder: The feeder is where the scrap metal is loaded into the machine. It can be manually or automatically operated depending on the model.

5. Binding Mechanism: This mechanism binds the compressed metal into a bale using wire, rope, or bands. The type of binding can vary based on the design and requirements.

6. Safety Features: These include interlocks, emergency stop buttons, and sensors to ensure operator safety during the operation.

7. Control Panel: This allows operators to manage and monitor the machine's functions, such as starting and stopping the compaction cycle, adjusting the speed, and monitoring the bale weight.

Operation Process

1. Preparation: Metal scraps are collected and sorted if necessary, then placed into the feeder.

2. Compaction: The feeder pushes the scrap into the compaction cylinder. The cylinder then applies force to compress the metal, creating a dense mass.

3. Baling: Once the desired density is achieved, the binding mechanism engages, wrapping the bale with wire or another binding material.

4. Ejection: After binding, the bale is ejected from the machine, ready for transportation and storage.

5. Maintenance: Regular maintenance, including cleaning, oiling moving parts, and checking for wear and tear, is essential to ensure the machine operates efficiently and safely.

Benefits

- Volume Reduction: Reduces the volume of scrap metal, making it more cost-effective to transport and store.

- Sustainability: Promotes recycling by efficiently handling scrap materials, reducing landfill usage.

- Safety: Designed with safety features to protect operators from potential hazards.

- Efficiency: Automates the process of compacting and bundling scrap, increasing productivity.

Conclusion: A Metal Scrap Baling Press Machine is an indispensable tool in the metal recycling industry, offering benefits in terms of efficiency, sustainability, and safety. Its use not only streamlines the recycling process but also contributes significantly to environmental conservation by promoting the reuse of materials.

We not only have these Baler Machine , but have other machines such as SK BalerVertical cast iron Chips briquetter,Iraq High quality Brass Turnings baler,Finland Y81F Scrap Metal Baling Machine,Ireland Big Volume Hopper Pop Cans Baling Machine,Portugal High quality Copper Borings baler,Chuangda baler Best performance Bronze Powder briquette machine,Mexico Hydraulic baler for Steel swarfs,Spain Automatic Used Metal Compactor,South Africa Y83 baler for Stainless Steel powder,Poland Small Waste Cans Baler,Turkey High density aluminum Shavings

Briquetting Machine,New Zealand 100Ton Used Beverage Cans Press Baler,Netherlands Tin Can Packing Machine,Canada Factory price metal Swarfs baling machine,USA Fast Aluminum Tins Recycling Baler,Kuwait

Hydraulic Copper Scrap Baler With Conveyor,Gaode baler, Automatic Pop Cans Compactor Machine,Denmark China Pop-Top Cans Baling Machine,Iran Heavy Duty Metal Scrap Shear With Conveyor,America Mobile Iron Scrap Crocodile Shear,Romania Big

Metal Scrap Press Baler,Tianfu baler Y83 Steel powder block making machine,Japan Vertical baling machine for Metal drillings,Ecuador Vertical briquette machine for Steel shavings,France China Supplier Used Beverage Cans Recycling Baler,Pakistan

High Density Briquette Machine for Aluminum swarfs,Albania Aluminum Chip Compactor For Sale,Bulgaria Turn Out Waste Steel Compress Baler,Qatar Push Out Iron Scrap Baling Press,Aupu machinery baler Low Cost Brass sawrfs block making machine,Britain Aluminum Tin Scrap Compression,Enerpat baler Vertical briquetter for Aluminum swarfs,Iceland China Bronze Millings briquette machine,Russia Vertical briquette machine for Stainless Steel borings,Belgium Vertical steel Turnings briquette machine,Malaysia Low Price Waste Steel Baling Machine,Ruf Briquetting Press Best performance Copper Hair Wire briquetting press,Dongfang hydraulic Alluminium Cans Crushe & Cube Machinary Baler,Singapore High density briquette machine for Aluminum shavings,Greece Y83 Copper Turnings briquetting machine etc...

Please contact with us if you have any questions.

Parameters:

| Model | CM125 | CM135 | CM160 | CM200 | CM250 | CM315 | CM400 |

| Chamber Size | 1200x700x600mm | 1400x900x700mm | 1600x1200x800mm | 1800x1400x900mm | 2000x1400x1000mm | 2500x1400x1200mm | 3000x2000x1300mm |

| Bale Size | 300x300mm | 350x350mm | 400x400mm | 450x450mm | 500x500mm | 600x600mm | 700x700mm |

| Bale Weight | 30-60kg | 50-90kg | 80-130kg | 120-200kg | 150-300kg | 400-600kg | 700-1000kg |

| Bale Density | 800-1200kg/m3 | 800-1200kg/m3 | 800-1200kg/m3 | 80-1200kg/m3 | 800-1200kg/m3 | 800-1200kg/m3 | 1200-1500kg/m3 |

| Motor Power | 18.5kw | 22kw | 30kw | 37kw | 22x2kw | 37x2kw | 45x2kw |

| Machine Weight | 6540kg | 7560kg | 11250kg | 16430kg | 19850kg | 28560kg | 38600kg |

| Machine Size | 4120x2150x1980mm | 4260x2350x2130mm | 4380x2460x2110mm | 4560x2650x2350mm | 4860x2980x2430mm | 5120x3150x2540mm | 5860x4650x2850mm |

Features:

> Latest design of the machine to let you use the best the machine all the time.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Stable hydraulic system to keep the machine run well.

> Schneider electrical components prolong the service life of the machine.

> The bale weight ranges from 40kg to 500kg, more options for your choices.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Adopts Two rams structure to keep high bale density.

FAQ:

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

> What is payment term of Automatic Scrap Metal Press Baler?

The payment of the baler machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the baler machine.

> How much price of Scrap Metal Compactor In A Factory?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> What all do I need to install the China Supplier Waste Steel Compress Baler?

After the

Metal Scrap Baler machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

> What is warranty time of the 160Ton Scrap Metal Compress Baler?

The warranty time of the baler machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

We provide training and installation services, we can guide you how to install, test, use, operate and maintain the baler machine for free, which also include video support, email services, and in a word, we can get everything done.

The single non-load cycle time is approx. 60 seconds, and we can make it faster or lower according to your requirement, such as 30 seconds one bale, or 90 seconds for one bale.